The Role of Robotics in Mechatronics

Mechatronics is an interdisciplinary field that combines mechanical, electrical, and computer engineering to design and develop advanced systems. These systems involve the integration of mechanical components, sensors, actuators, and controllers to create intelligent machines that can perform complex tasks. Mechatronics has revolutionized the manufacturing industry, enabling the creation of highly automated production lines that can operate with precision and efficiency.

Robotics is a key component of mechatronics, providing the intelligence and automation necessary to create advanced systems. Robotics involves the design, construction, and operation of robots that can perform tasks autonomously or with minimal human intervention. Robots can be programmed to perform a wide range of tasks, from simple repetitive actions to complex decision-making processes.

Robots are widely used in the manufacturing industry, where they can perform tasks such as welding, painting, and assembly. They are also used in healthcare, agriculture, and logistics, among other industries. The integration of robotics into mechatronics has led to the development of advanced systems that can operate with high precision, speed, and accuracy.

In this article, we will explore the role of robotics in mechatronics and how it has transformed the manufacturing industry. We will examine the benefits of using robots in mechatronics, the challenges involved in their integration, and the future of robotics in mechatronics.

The Role of Robotics in Mechatronics

Mechatronics is an interdisciplinary field that combines mechanical, electrical, and computer engineering to design and develop intelligent systems. Robotics, on the other hand, is a branch of engineering that deals with the design, construction, and operation of robots. Robotics plays a significant role in mechatronics by providing advanced automation solutions that enhance the performance, reliability, and efficiency of mechatronic systems.

Advantages of Robotics in Mechatronics

Robotics offers several advantages in mechatronics, including:

- Increased productivity and efficiency

- Improved accuracy and precision

- Enhanced safety and reliability

- Reduced labor costs

- Ability to perform complex tasks

Applications of Robotics in Mechatronics

Robotics is used in various applications in mechatronics, including:

- Manufacturing: Robots are used in manufacturing processes to assemble, inspect, and package products.

- Healthcare: Robots are used in healthcare to assist in surgeries, rehabilitation, and patient care.

- Agriculture: Robots are used in agriculture to perform tasks such as planting, harvesting, and monitoring crops.

- Transportation: Robots are used in transportation to automate processes such as loading and unloading cargo and guiding vehicles.

- Space exploration: Robots are used in space exploration to perform tasks such as collecting samples and conducting experiments.

Challenges and Future of Robotics in Mechatronics

Despite the advantages of robotics in mechatronics, there are also several challenges that need to be addressed, including:

- High costs of implementation

- Need for specialized skills and training

- Limited flexibility and adaptability

- Safety concerns

However, the future of robotics in mechatronics looks promising, as advancements in technology are making robots more affordable, intelligent, and versatile. Robotics will continue to play a critical role in mechatronics, as it enables the development of innovative and efficient systems that can improve our lives and transform industries.

Overview of Mechatronics

Mechatronics is a multidisciplinary field that integrates mechanical, electrical, and computer engineering with control systems and robotics to design and develop advanced automated systems. It involves the design, development, and control of advanced systems that combine mechanical, electrical, and software components to achieve high levels of automation and precision.

History of Mechatronics

The term “mechatronics” was first coined in Japan in the 1960s to describe the integration of mechanical and electrical engineering in the development of advanced systems. The field has since expanded to include computer engineering, control systems, and robotics, and has become an integral part of modern manufacturing and automation.

Components of Mechatronics

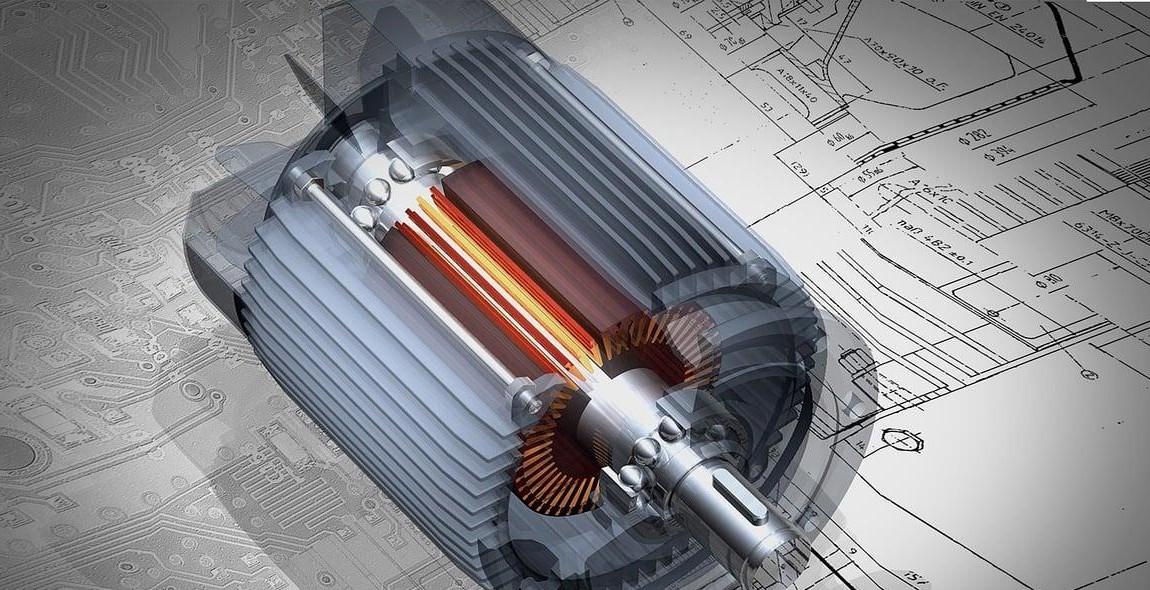

The main components of mechatronics systems include mechanical components such as sensors, actuators, and motors, electrical components such as circuits, power supplies, and control systems, and software components such as programming languages, algorithms, and data analysis tools.

Mechatronics systems are designed to perform a wide range of tasks, from simple repetitive tasks such as assembly line operations to complex tasks such as autonomous navigation and control of robots. They are used in a variety of industries, including manufacturing, aerospace, healthcare, and transportation.

The integration of mechanical, electrical, and software components in mechatronics systems requires a multidisciplinary approach that involves experts in each of these fields. Mechatronics engineers must have a strong understanding of mechanical and electrical engineering principles, as well as programming and control systems, to design and develop advanced automated systems.

| Mechatronics Components | Description |

|---|---|

| Mechanical Components | Sensors, actuators, motors, gears, and other mechanical components used to control and manipulate physical systems. |

| Electrical Components | Circuits, power supplies, and control systems used to power and control mechatronics systems. |

| Software Components | Programming languages, algorithms, and data analysis tools used to develop and control mechatronics systems. |

Overview of Robotics

Robotics is an interdisciplinary field of engineering and science that deals with the design, construction, operation, and use of robots. A robot is a machine that is capable of carrying out a complex series of actions automatically, especially by being programmed by a computer.

History of Robotics

The history of robotics dates back to ancient times when Greek mathematician Archytas of Tarentum designed a wooden pigeon that could fly through the use of steam. However, it wasn’t until the 20th century that robotics became a field of study and development. The first modern robot was developed in 1954 by George Devol, who invented the Unimate, a robotic arm designed for use in a General Motors factory. Since then, robotics has rapidly evolved and is now used in a wide range of industries, including manufacturing, healthcare, and entertainment.

Components of Robotics

A robot is made up of several components, including a controller, sensors, actuators, and effectors. The controller is the brain of the robot and is responsible for receiving and processing information from the sensors. Sensors are used to detect and measure different aspects of the environment, such as light, sound, temperature, and pressure. Actuators are used to move the robot and its parts, while effectors are used to interact with the environment. In addition, robots are often equipped with software and programming languages that enable them to perform specific tasks.

In conclusion, robotics is a rapidly evolving field that has the potential to revolutionize the way we live and work. By combining the principles of engineering, science, and computer programming, robotics has enabled us to create machines that can perform complex tasks automatically, making our lives easier and more efficient.

Advantages of Robotics in Mechatronics

Robotics has become an integral part of the field of mechatronics, and for good reasons. The use of robots in mechatronics has numerous advantages that make them a preferred choice for many industrial and manufacturing processes.

Increased Efficiency

One of the most significant advantages of robotics in mechatronics is the increased efficiency they offer. Robots can perform repetitive tasks with precision, speed, and consistency, which is impossible for human workers to match. This increased efficiency leads to higher production rates, improved quality, and reduced cycle times. Additionally, robots can operate 24/7 without getting tired, ensuring optimal production levels and minimal downtime.

Improved Safety

Another crucial advantage of robotics in mechatronics is the improved safety they provide. Robots can handle hazardous and dangerous tasks that would otherwise put human workers at risk. They are also equipped with sensors and safety features that allow them to detect and avoid obstacles and hazards, preventing accidents and injuries in the workplace.

Cost Savings

Integrating robotics in mechatronics can result in significant cost savings for industries and businesses. Robots can perform tasks faster and with greater precision, reducing the need for manual labor, which can be expensive and prone to errors. Additionally, robots require minimal maintenance, which translates to lower maintenance costs and reduced downtime. Overall, the use of robotics in mechatronics can lead to increased profitability and competitiveness for businesses.

| Advantages | Description |

|---|---|

| Increased Efficiency | Robots can perform repetitive tasks with speed, precision, and consistency, leading to higher production rates and reduced cycle times. |

| Improved Safety | Robots can handle hazardous tasks and are equipped with safety features that prevent accidents and injuries in the workplace. |

| Cost Savings | Robots can reduce the need for manual labor, require minimal maintenance, and lead to increased profitability for businesses. |

Applications of Robotics in Mechatronics

Robotics has revolutionized the field of mechatronics and has become an essential component of various industries. With the ability to perform repetitive and complex tasks with high precision, robots have increased efficiency and productivity while reducing costs. Here are some of the applications of robotics in mechatronics:

Manufacturing

Robotics has transformed the manufacturing industry by automating various processes such as assembly, painting, and welding. With the use of robots, manufacturers can produce goods with high precision and quality, while reducing the risk of workplace injuries. Additionally, robots can work around the clock, increasing production output and reducing costs.

Healthcare

Robots are increasingly being used in healthcare to assist with surgeries, rehabilitation, and patient care. Surgical robots can perform complex procedures with greater precision and accuracy, reducing the risk of human error. Rehabilitation robots can help patients recover from injuries or disabilities by providing tailored exercises and monitoring progress. Furthermore, robots can assist in patient care by providing companionship and assistance with daily tasks.

Military and Defense

Robots have been used in military and defense for various applications such as reconnaissance, bomb disposal, and search and rescue. With the ability to operate in hazardous environments and perform dangerous tasks, robots can reduce the risk of injury or death to human personnel. Additionally, robots can be used to gather intelligence and provide situational awareness to military personnel.

Agriculture

Robots are increasingly being used in agriculture to automate various tasks such as planting, harvesting, and monitoring crops. With the use of robots, farmers can increase efficiency and productivity while reducing costs. Additionally, robots can provide real-time data on crop health and yield, allowing farmers to make informed decisions about crop management.

| Industry | Application |

|---|---|

| Manufacturing | Assembly, painting, welding |

| Healthcare | Surgery, rehabilitation, patient care |

| Military and Defense | Reconnaissance, bomb disposal, search and rescue |

| Agriculture | Planting, harvesting, crop monitoring |

Challenges and Future of Robotics in Mechatronics

As the world of mechatronics continues to evolve, robotics has become an increasingly important component of this field. However, there are several challenges that must be addressed in order to fully realize the potential of robotics in mechatronics.

Challenges

- Cost: One of the biggest challenges facing the robotics industry is cost. Robots can be expensive to design, build, and maintain, making them inaccessible to many small and medium-sized businesses.

- Integration: Integrating robotics into existing mechatronic systems can be challenging, as it requires a deep understanding of both technologies.

- Safety: Safety is a major concern when it comes to robotics, as they can be dangerous if not properly designed and maintained.

- Regulations: Regulations surrounding the use of robotics in mechatronics are still being developed, which can make it difficult for businesses to know how to properly implement these technologies.

Future of Robotics in Mechatronics

Despite these challenges, the future of robotics in mechatronics looks bright. As technology continues to advance, robots are becoming more affordable, easier to integrate, and safer to use. Additionally, regulations are starting to catch up, which will provide businesses with clearer guidelines on how to use robotics in mechatronics.

One area where robotics is expected to play a major role in the future of mechatronics is in the field of automation. Robots can be used to automate many tasks, freeing up human workers to focus on more complex or creative work. This will not only increase efficiency and productivity but will also lead to new job opportunities in the field of robotics.

| Advantages of Robotics in Mechatronics | Disadvantages of Robotics in Mechatronics |

|---|---|

| Increased efficiency and productivity | High initial cost |

| Improved safety in hazardous environments | Integration challenges |

| 24/7 operation | Regulatory uncertainty |

Overall, the challenges facing robotics in mechatronics are significant, but the potential benefits are even greater. As technology continues to advance, we can expect to see even more innovative uses of robotics in this field.